Aquamesh Inventors Celebrate 40 Years in Business

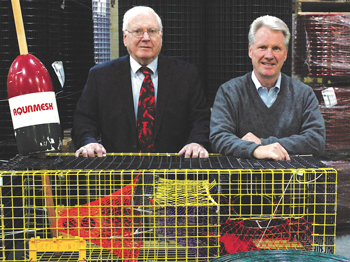

Jim Knott Sr., left, and Jim Knott Jr. at their Riverdale plant in Northbridge, MA. Aquamesh welded wire mesh, which Jim Knott Sr. developed, was used in the lobster trap shown. Aquamesh is made in the Northbridge plant and used in 80% of lobster traps. Riverdale Mills photo.

The history of Riverdale Mills is a story of passion and perseverance. As the company opened its doors for the first time, U.S. manufacturing had yet to recover from two recessions and many doubted the future of the sector.

But James Knott Sr. was a recreational lobsterman and entrepreneur who took issue with the design and durability of the wood and twine lobster traps. Punishingly heavy to haul out of the water, rapid corrosion of fasteners and the wood weighed heavily on the lobstermen’s backs and wallets. Knott enlisted his sons and set out to design a better trap. After years of trial and error, the family invented Aquamesh®, the first-of-its-kind marine wire mesh used for building the modern-day lobster trap.

In 1980, the first rolls of Riverdale Mills’ Aquamesh® were shipped to the fishing villages of Maine and the rest, they say, is history. Today, over 80 percent of lobster traps made in North America are made with Aquamesh and the mesh is used by fishermen around the globe.

Riverdale Mills has a unique history and an intense focus on innovation and long-term success. This was evident when, in the spring of 2015, Jim Knott, Jr. was made CEO. Jim had worked at Riverdale Mills, since its founding, in a variety of financial, technical and operational positions. His deep-rooted knowledge of the business proved invaluable as Riverdale Mills transitioned from a start-up, with sales initially limited to New England, to an internationally recognized leader in the wire industry.

“I was lucky to work with my father for over 30 years. He believed strongly in Riverdale Mills and that our products would always be manufactured in the United States. He never shied away from protecting his company and the lobster industry,” said Knott.

Knott acknowledges the keys to the company’s success lie in a deep-rooted dedication to employees, an unwavering determination to deliver superior products, and a commitment to staying ahead of business developments, industry trends and, most importantly, the customer’s needs. “We exist, have always existed, to help lobstermen lobster better,” said Knott.

The success of Aquamesh naturally spawned new applications for the wire mesh. Oyster farmers adopted the mesh to build off-bottom oyster cages, a system of wire cages floating on pontoons that suspend the oysters just below the surface of the ocean where the water is warm and the oyster’s food source is more plentiful. Knott said, “It is an ideal system, particularly in the northeast, that allows oysters to fully mature in half the expected growth time of 7 years.”

The off-bottom oyster industry now employs a diverse group of aquafarmers – from young generations to seasoned lobstermen and women who still yearn to earn their living from the sea without the challenges and unpredictability of fishing on the open ocean.

Along with innovation (the company now manufactures 3,500 configurations of welded wire mesh) environmental stewardship is a core principal on which Riverdale Mills was founded. The company operates dozens of large industrial machines 150 hours a week. Achieving maximum energy efficiencies is not easy. But, according to Knott, eco-friendly and energy efficient manufacturing is “right for the planet and essential for the safety and sustainability of our company, our products and the community in which we operate.

Knott said, “For 40 years, Riverdale Mills has been admired for its can-do attitude, ingenuity, and innovation.” At this milestone, Knott is focused the future but holds close the relationships he has built with his customers.

“We are who we are today because of the support of lobstermen and women,” said Knott. The lobster fishing industry put us on the map, and we are deeply grateful. No matter where we go, or what products we sell, it always comes back to the welded wire mesh lobster trap. The lobstermen expect nothing but the best from Riverdale Mills. Knowing that keeps us focused on manufacturing great products and delivering even greater customer service.”

Riverdale Mills was deemed an essential business by MA Governor Charlie Baker because its wiremesh is critical to the marine industries. The company remains open for business.