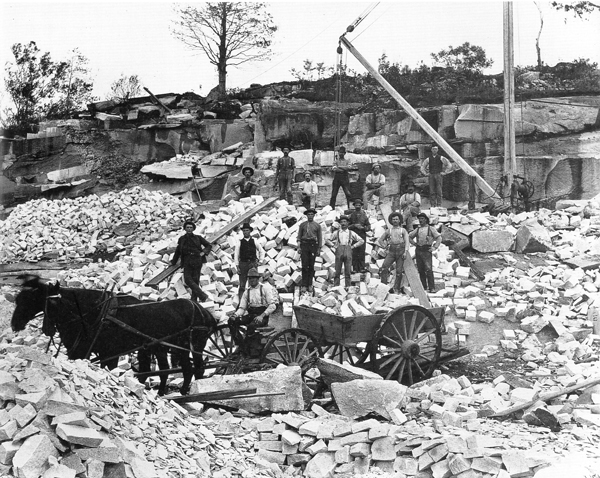

B A C K T H E N

Paving Blocks

Paving-block cutters at the Maine and New Hampshire Granite Co. quarry at North Jay, probably in the early ’90s. This quarry produced as many as one million blocks per year. In 1889, Maine produced nearly 18 million blocks out of a national production of 62 million. In 1895, approximately half of the output of the state’s 153 quarries was for street work, mostly paving and curbing.

Although Boston laid some Quincy granite blocks in streets in 1840, and there is record of a Warren brig carrying paving blocks to New Orleans in 1845, the widespread use of granite paving blocks came after the Civil War. Boston had previously tried both cobblestones and New Jersey trap rock. On New York’s Broadway, the ultimate proving ground, cobblestones sank under heavy traffic. Beginning in 1853, “Russ” pavement, consisting of large, square granite blocks, set in cement, with cut traction grooves, were tried. These worked well until the grooves wore down and it was discovered that the effects of horseshoes, wagon tires, and atmospheric action had rendered the stone too hard to be recut.

The first granite “New York blocks,” a foot or more long, eight to ten inches wide, and six inches deep, proved ruinous to horses, which could not gain sufficient traction. A “New York” paver, eight to twelve inches long, seven to eight inches deep, and three and one-half to four inches wide, was a great improvement. By 1892, this block amounted to three-quarters of Maine’s production. (For reasons all too well understood by politicians, thirty-two different paving-block sizes would eventually be specified by various cities.) Proper paving stone was hard and brittle, else it became excessively slippery.

The paving-block industry began at Cape Ann and spread quickly to Maine. In big cities, paving became a public issue. Newspapers decried the filth of muddy streets, teamsters whipped their mired teams, and politicians, we may be confident, salivated over the opportunities offered for personal enrichment. Early paving block centers were Vinalhaven, West Sullivan and Sullivan, Frankfort, and Tenants Harbor. Most paving was cut from waste stone. Maine was slow to pave her own streets. Bangor had no paved streets until 1882. Rockland’s notoriously muddy Main Street, supposedly once navigated by a row boat, was not paved until the ’90s. While Maine blocks were shipped to St. Louis, Chicago, Baltimore, Washington, Philadelphia, New Orleans, and elsewhere, the greatest market was New York. An observer wrote in 1892:

Some wonder where all of the [Maine] paving go that are made, but if one will visit the great cities of New York and Brooklyn alone, and see the miles of unpaved avenues and streets that are awaiting their turn, the wonderment will cease.

At certain locations, particularly at Sullivan and West Sullivan, South Thomaston, and St. George, where the granite lay in thin sheets, many one- and two-man paving-block operations, called “motions,” appeared; landowners discovered that they could receive stumpage for barren property long considered worthless. Motion workers, living on store credit, usually sold a season’s worth of blocks at one time. They were, therefore, ripe for the plucking by swindling paving pirates. At one point, independent paving cutters in Knox County joined forces to sell through a single agent. At the height of demand, the agent absconded with all the cutters’ money for their year’s work, leaving them broke and in debt.

The first paving cutters were Scotch, later joined by English, Welsh, and Irish, and, still later, Swedes and Finns. Some locals also tried their hand at it. Many cutters were single, shifting about as opportu-nities presented themselves. The chief qualifications were great strength and endurance, and the ability to quickly “read” the stone’s fracture characteristics. According to a state labor agent in 1892:

To form this paving requires skill, and there is no fear of our paving cutters being supplanted by their wives or children. Using hammers weighing twenty-six pounds is no child’s play, and yet the lightest of these men will use those big hammers with ease. The work is healthy, as they are not obliged to work in the dust like the granite cutters. The use of the big hammers keeps the shoulders back and there is not a paving cutter that follows the business but what is not as straight as an Indian.

This is a very early reference to the dangers of breathing stone dust. The wagon is a dump-cart fore-cart combine.

Text by William H. Bunting from A Days Work, A Sampler of Historic Maine Photographs, 1860–1920, Part II. Published by Tilbury House Publishers, 12 Starr St., Thomaston, Maine. 800-582-1899.