Tending a trap at the rail. All the boat controls necessary while hauling are behind the fisherman; the wheel to steer and the sheet (line) to tend the mainsail. The work area in the cockpit is about 6’x12’, but most of the work is done in the area around the wheel. Photo: Fishermen's Voice |

He is not a lobsterman, but a guy who wanted to sail and needed a practical reason to do it. So he started taking people out in the early 1990s to show them how traps were hauled under sail. He first did this in a sloop he built for that purpose. He has said “the genius of the sloop boat design is in its ability to stop.” The sloop can be stopped and will sit on its gear, allowing the lobster gear to be hauled straight up, a necessity, among other things, in avoiding entanglement with any nearby gear.

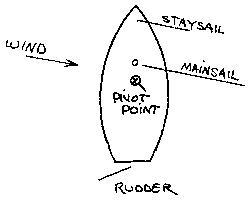

Unlike most sailboats which have a pivot point at the mast, the sloop boat’s pivot point is a few feet behind the mast. This contributes to the boat’s ability to stop and lay to.

The typical sloop boat of 28 feet carried a gaff rig mainsail of about 450 square feet with two or three reefs. The mainsail was reefed when hauling. The boom extended two or three feet beyond the stern. It carried a jib set on a 10-foot bowsprit and a balanced staysail or jumbo, pivoted at a point one-quarter of the way back of the front end of its boom at the bow. The staysail, between the main and the jib, is self-tending. It has one sheet set at a fixed length and shifts position as the boat is tacked. The jib, good for speed on a passage, is lowered while hauling.

The mainsail is controlled by its sheet, with blocks, traveller and a knot at the end of the sheet. Along with the rudder, speed, steering and stopping are controlled with these two pieces of equipment.

The approach to a buoy is made downwind and closehauled. When the buoy is just off the bow, the mainsail is let out giving the boat a leeward helm. This is countered with the rudder to slow the boat as the buoy is grabbed. The boat is then headed in the direction of the buoy line, which is usually off into the wind. The boat’s momentum carries it toward the gear. When over the gear the rudder is turned up to leeward.

With the mainsail out over the side and luffing, the trap is hauled. At about the time the trap is brought aboard the boat is heading off the wind. The rudder is then thrown up to windward to make the boat lay to while tending the trap. The trap is emptied, baited and returned to the water while the boat is laid to, stopped by the sail and rudder countering each other’s effect on motion. The wind pushes the bow off, the resulting forward motion on the rudder sends the bow back into the wind without enough force to cross through.

Sketch showing position of the sails and rudder when the boat is laying to or stopped in the water. Any forward motion causes the rudder to counter it by bringing the bow around. Hauling in the mainsail gets the boat under way. |

Hauling is done aft, aside the tiller or wheel. Sloop boats with a wheel had a worm gear that held the rudder in position. The more common tiller had a comb under the aft end. This brass arc with notches allowed the tiller to be dropped into the notches and set at different positions. The trap is hauled hand over hand and put on the wash rail while it is rebaited. Afterward, it is returned to the water, the rudder is brought down and the mainsail hauled in putting the boat under way. Harold says, “from approaching the buoy to getting underway again takes about three minutes. Some fishermen sailed up to a buoy, brought it aboard and with the momentum of the boat brought the trap off the bottom and toward the surface. They would then sail back around in a circle while tending the trap. The baited trap would be set as they sailed back over the area where they had picked it up. Their path was a series of loops over the traps. More effort than laying to, they had to jibe, tend the mainsail and steer while tending the trap.”

Tides, currents, water depth and wind conditions could require adjustments being made to some or all of these maneuvers in any particular situation. Changes in conditions had a greater impact on the operation of sloop boats than they do on modern boats. Fishermen had to work more with the tides in these boats. Some traps might be left on a particular day until tide or winds were more favorable.

Sloops could set a dozen or so traps at a time. Double parlor wood traps were set as singles. Hauling about 60 a day was typical, although there are stories told of 150 traps being hauled in one day. Hauling by hand is not as difficult as might be imagined, at least in good weather. Less then great weather and sea conditions could obviously compound the difficulty. And the sixtieth trap would have been a bit more difficult to get up than the first. But it appears few if any sail boats were as well suited to the task as the sloop boat. The sloop’s ability to lay to was as important to fishermen as its speed. Harold Burnham has said that, “contrary to everything our modern sailing culture teaches us, these boats were designed to stop.”

Harold Burnham’s boat shop and charter business is at 141 Main St., Essex, Mass.

|