The automated welder can do several dozen welds simultaneously. It pours out ribbons of 10 foot wide wire mesh continuously. The row of lights from lower right to upper left in the photograph, are sparks from the intersected wires being welded. The narrow edged bar drops down to make a weld, lifts while the mesh moves ahead and the bar dops again to weld. Photo: Fishermen's Voice |

To make the first mesh for a trap, he hand welded wire mesh and coated it. He gave some to a Gloucester lobstermen who nailed it over his wood traps. From there it was a hit and miss attempt to get fishermen to try it. Knott began making wire traps and then dipping the whole trap in plastic.

It was a hard sell convincing lobstermen to try them. He tells the story of setting a trap up on a table at a trade show in Boston. It was a green wire trap on a white tablecloth. Knott was there in a suit and tie watching as an elderly, hunched over fisherman slowly walked passed the table. His comment to Knott while passing and looking over at the trap was, “Looks pretty, but it ain’t gonna catch no goddamn lobster.”

It was later, when he contacted lobstermen who were catching a lot of lobster, high-liners, that some of them were willing to try the new trap. They also had the money to invest in them. Other fishermen saw these high-liners using them, catching lobster, and began trying them in the late 1970’s. By the 1990’s Knott’s company had a major share of the market for the wire mesh, which by that time was on its way to becoming the standard material for lobster trap construction. In about a five-year period, in the late 1980’s, most all lobstermen switched over to wire traps.

By the time that wire lobster traps were taking over, Knott’s patent had expired and other manufacturers were competing. Now there are other wire mesh manufacturers in the United States, Italian mesh has gained a foothold and more recently a Chinese version has jumped into the mix.

That’s the short version of the story. When Knott decided to go full tilt on wire mesh for lobster traps he borrowed money and bought a boarded up 1840’s brick mill in Northbridge, Massachusetts. It was 10 miles east of Worcester and 50 miles from salt water. The windows were all broken, and nothing worked in the building. Originally, scythes were manufactured there for America’s rural economy before being converted to a bayonet factory during the Civil War. But it was what he could afford for the space he needed.

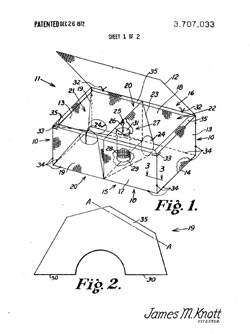

The original 1972 drawing on the patent for the “structure” that became the wire lobster trap. |

The abandoned, leaking building had 20,000 square feet of usable space, but also had assets not apparent to those in the market for a metal building in an industrial park. The river that ran under the building provided energy to the belt driven machinery well into the twentieth century. Knott converted that waterpower to electric generation that today produces $100,000 worth of electric power annually. There were railroad tracks that ran along side the building that were good for shipping the company’s many tons of wire. Between the tracks, the river and the old building was acreage for expansion, and that was rapidly filled when the wire lobster trap took off.

There were plenty of details to work out in both the design and the manufacture of a product that would become the accepted standard for people who made their living with it. When the right wire diameter was determined, getting that gauge, and a lot of it was one of the first projects. A machine was built to take the 1/4” diameter wire and stretch it through a series of dies down to the gauge they needed.

Today a larger machine runs giant spools of this 1/4’ wire, joined into a continuous length, though dies, sending the thinner wire onto spools and then on to the welder. A major turning point in the production line was the purchase, in 1979, of an Austrian, custom built, computer driven welding machine. This welder welds, simultaneously, all 81 intersections of a line wire (length) with a cross wire in typical, 1 1/2”inch square mesh that is 10 feet wide. It operates like a press, with an 11-foot long narrow bar coming down on the intersecting wires stretched on a metal bed. An electric charge welds all the intersections at once. All day long this welder pours out ribbons of welded mesh. It is then machine cut to specified widths and rolled up.

During the zinc coating process, zinc collects around the welds and protects that vital joint. The zinc coated mesh is then sent across the flat bed of an oven. From there it goes directly through the “fluid bed.” The fluid bed is a chamber where PVC plastic has been churned up into a thick cloud that is effectively a fine powder in a liquid state. The hot metal melts the tiny plastic particles that touch it, collecting in a uniform thickness over all the surfaces of the mesh. The bulking of zinc at the joints creates more surface area for the protective plastic coating, redoubling the durability of the joint.

Making a good product and marketing that product are different departments. Knott had to be both builder and booster. A self-described builder, who helped pay his way through school as a building contractor, he took easily to building the buildings and machinery that is now Riverdale Mills. He built with his own hands some of the machines he used to start the company.

The patents had run out by the time the fishing industry was sold on wire traps in the 1990’s. By then Knott was making coated wire mesh for all kinds of things. Business was booming in the late 1990’s.

Giant spools of 1/4" wire are welded end to end to form a continuous length feed into the machinery. The wire is stretched to 1/3 its diameter forming miles of wire that goes to spools, welders, machine cutters, zinc coaters, plastic coaters, and packers before being shipped to lobster trap builders. Photo: Fishermen's Voice |

One morning in November 1997, the roar of many boots charging up the wood stairwell in the old factory clock tower was heard. Then 23 armed men with “police” emblazoned across their chests, stormed into Knott’s office at the mill. He was told they were going to confiscate documents for the Environment Protection Agency. Their spokesman refused to show a warrant. Keeping in mind that Knott had finished school and the army 45 years earlier, he refused to let them pass, telling them he would have them arrested if they didn’t leave immediately. They handed over a warrant. Later he learned the invasion was over alleged discharges into the river.

The story appeared in the Boston Globe. The story was picked up by 60 Minutes, who featured Knott on the national television show. He was a victim of overzealous, over-reaching, under informed armed members of the police union, as Knott described it. Faced with a $1.5 million dollar fine and 6 years in jail, he refused the prosecutors offer of a settlement. He thought guns were unnecessary, knew he had done nothing wrong and eventually spent $250,000 for his day in court. The issue was a lemon juice strength acid used to etch metal for coating. Knott knew the rinse liquid was dilute and neutralized before discharge. Hiring chemists and lawyers, he brought the EPA to the mat, winning the case nine months later with a judge’s 17-page decision.

The 20,000 square foot scythe mill has grown to 392,000 square feet, about nine acres. The line of wire mesh for lobster and other traps has expanded to include other wire-based products. One of those products is a heavy-duty security fence. Not long ago, the representative of a Middle Eastern country came to Knott with a proposal to put a wire security fence around the whole country. When they insisted on having a plant built over there to do it, the plans fell apart.

Change sometimes comes hard, but the new traps are definitely catching lobster. There are several million wire lobster traps in Maine alone. Everyday a few million are handled, and most of them are thrown overboard.

|